In mold label package for personal care products

VSOP offset printing is a big thing for label printing and flexible printing and changes the packing industry greatly. GH Printing have applied this technology to label printing for about 11 years and we are so proud of being the first one in China to provide this lead edge technology.

Category:

In Mold Label

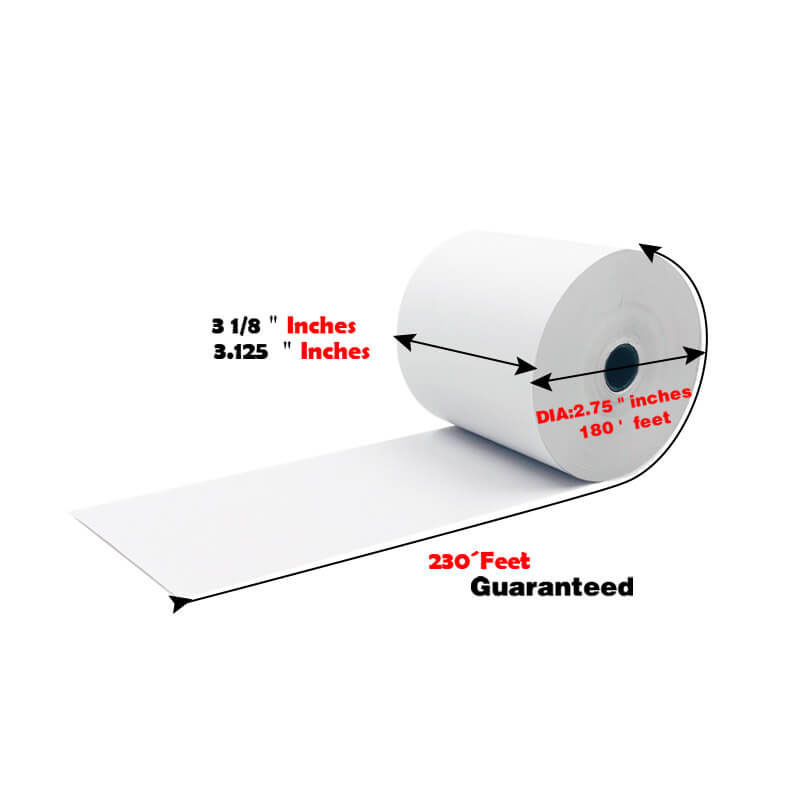

Keywords: Thermal paper roll printing

E-mail:

In mold label package for personal care products

Details

Description

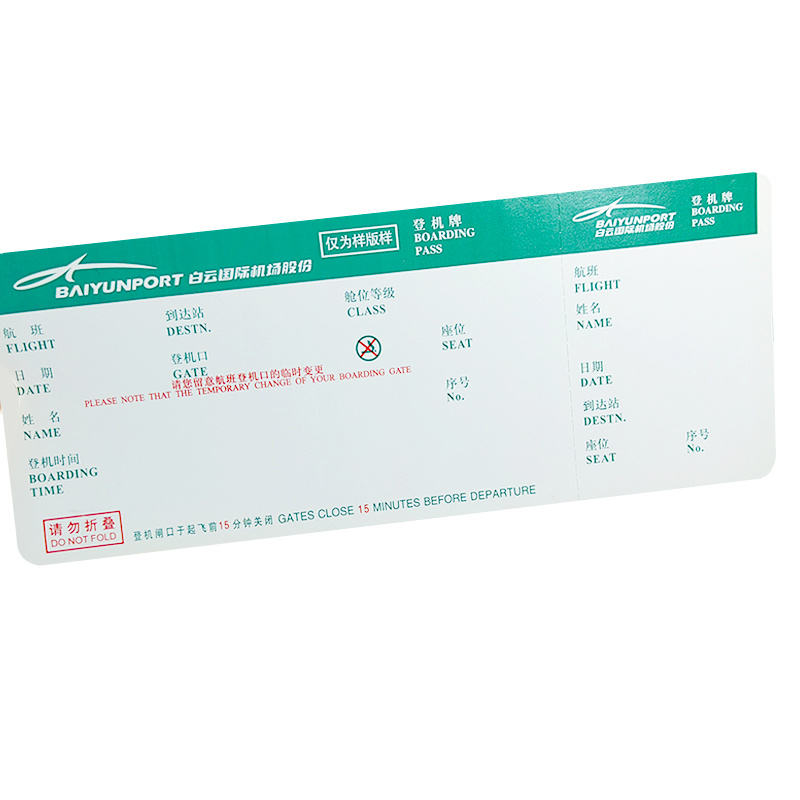

OEM Printing whole sale good supplier chemistry iml in mold label

GH Printing is the first one in China to apply VSOP offset printing to make in mold labels. It not only can prevent the IML Label from static electricity with our professional specialists and advanced VSOP printing press; but also can reduce the bubble with our own techinique which happened in many printing companies.

In mold label can be printed with various printing technologies including flexography, digital, offset and other printing technologies but VSOP offset is the most recommended for printing IML labels. The prime factors powering the demand for in mold label is a growing demand for food packaging, complete recyclability, no label look, no requirement of glue, and a saving in time and effort in post-labelling.

You can watch the video how we make the IML labels!

| Printing Method | Offset Rotation (VSOP); Flexo Printing; HP Indigo |

| Size and Thickness |

Customized; Max. Length: 732mm; Max. Width: 520mm |

| Colors & Effect | Up to 9 Colros; Gold Stamping + Screen Printing + Laminating |

| Ink: | UV Enviromental Ink |

| Advantages |

– Low Start-up Cost; No Plate Cost; – Variable Print Lengths; – Superior Print Quality; – Short Delivery Time; – Any Kind of Substracts Availabel: Paper, Foil, Film etc; – Affordable Even in Small Run. |

Specification Copy

To achieve a good IML production it is highly recommended to avoid static electricity, otherwise the labels will stick together and double-picking will be a major problem. Every process step must have either a passive or an active static discharge station at the end. For priming, it is very important in case of offline coating. High static may introduce pin holes in the primer layer, causing print quality issues.

Next

Get a free product quote

Yuegang Company adheres to the business philosophy of "integrity, pragmatism, people-oriented, keeping pace with the times, and pioneering innovation", striving to achieve the quality goals of product factory pass rate of 99.9% or more and customer satisfaction rate of 98% or more.