About Us

High-quality and inexpensive professional printing brand

Offset Labels

• High Quality: The offset printing process means you will get the highest quality of fine images. In some ways, this can be seen as a more “premium” option than digital. Offset also gives you the best color matching as it uses actual Pantone inks.

• Versatile: Unlike digital printing, offset printing can work on a very wide range of printing surfaces. These include paper, wood, fabric, metal, leather and plastic. This gives you more options in terms of packaging design, so it allows you to be more imaginative.

• Cheaper in Large Quantities: While the setup cost for offset printing is higher than digital printing, the unit cost is significantly lower. This means that for very large quantities of products, choosing this option is overall much more economical. Digital is starting to catch up in this area, but still can’t compete in terms of unit cost. Also remember that digital printing uses four-color printing, so if you only want to print in black and white, using offset might be cheaper.

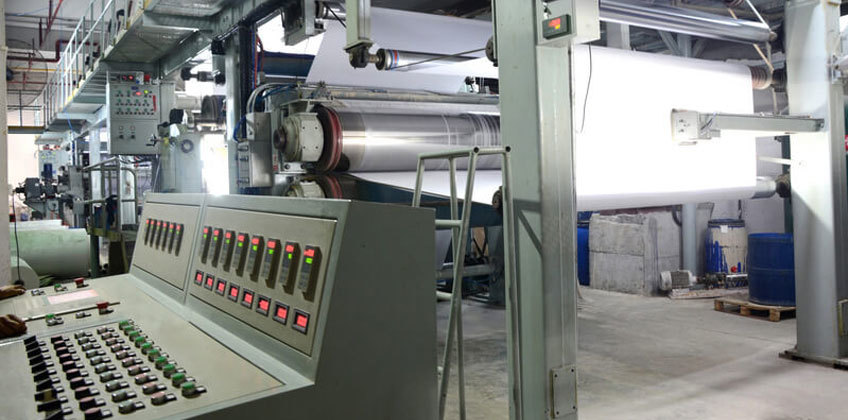

Flexographic Labels

Flexographic labels are a highly versatile label solution that can be applied to virtually any packaging. They can be printed on a variety of materials, including metallic films, plastics and paper.

Digital Label Printing

Digital label printing is a rapidly developing technology that is transforming the label industry. New printers are coming to market every year, improving the quality of available labels while reducing printing costs and turnaround times.

Digital Advantages

• Fast: Digital label printing offers shorter turnaround times, so it’s very useful for those last-minute orders or when you have very tight deadlines. This is because the image can be created directly on screen, without the need to generate plate images.

• Cheaper in Small Quantities: If you only need a small number of labels—perhaps for a limited edition product or a one-off promotion—then digital printing might be the more economical option. This is because, while the individual unit cost of digital labels tends to be higher, the initial setup cost for offset printing is higher, as you have to consider creating the image on the plate. Most of the mechanical processes involved in offset setup are not digital. If you add all of this together, then for small order quantities, digital will be cheaper.

• Consistent Image: With digital printing, you can ensure that the image is the same every time. This will make your overall product look very professional, and it also means less waste—which, of course, reduces costs. This high degree of accuracy is mainly because, using digital plates, you don’t have to consider getting the right ink balance during the printing run.

• Customizable: For numbers, you can also opt for variable data printing. This is a customizable form of printing that uses information from a database, allowing the text and graphics on each piece to change without stopping the press. For example, you may wish to personalize products by printing each person’s name on individual labels. This is commonly used for direct marketing purposes.

Offset Advantages

Flexographic Labels

Gravure printing, a photomechanical intaglio process, in which the image to be printed consists of recesses or grooves in the surface of the printing plate. The process is the opposite of relief printing, in which the image is raised from the surface of the printing plate. The printer forms the image by hand-cutting the printing plate or by using acid or other chemicals to etch the plate along the lines of the desired image. The printer then covers the plate with ink and wipes the ink from the higher surfaces, leaving the recessed or intaglio areas filled with ink. Paper pressed against the plate then absorbs the ink from the recessed areas. Varying the depth of the recesses provides tonal gradations in the printed image.

Thermal Coating

Thermal labels are cost-effective labels made using a thermal printing process. In this process, a thermal print head is used to selectively heat specific areas of coated thermal (or thermochromic) paper. The paper passes over the thermal print head, and then turns black where it is heated, thus producing the desired image. Two-color thermal printing can create red and black images by heating at two temperatures. Thermal labels do not use ink, toner, or ribbons, only chemically treated thermal material.

Screen Printing Labels

Screen or stencil printing labels are a flexible way to help many products come alive on the shelf. Screen printing is a technique that involves applying a mesh pattern to the surface of a product, then pressing or pumping ink through the mesh onto the product to produce an image.

Cold Foil Labels

Custom foil labels are a useful tool to attract customers browsing the store aisles. There are two main types of foil labels: hot foil labels and cold foil labels. Hot foil labels are made by using a heated die to press metallic dry ink onto the label material. Cold foil labels are made by using a printing press to apply a thin foil sheet to the label material using a cold die and UV curing lamp.

Embossed Labels

Embossed labels allow you to add custom designs, lettering, decorative, or patterned effects to your product packaging.

Variable Printing

Variable printing allows us to print large quantities of labels while changing content elements at an individual level. At Resource Label Group, we are able to print content changes without stopping or slowing down the printing process.